Going with the lowest bid might seem to be an attractive option. However, the saying “buy cheap pay twice” could not be more true when it comes to construction projects. Experts point out that cutting costs for critical competences, such as project management, can lead to costly downtimes and unforeseen situations, inflating the budget, causing delays and, therefore, eroding profits.

“Anyone with experience in construction knows that proceeding strictly as planned can be quite a challenge: unforeseen problems arise at building sites, shortages of materials occur and delays become inevitable. In fact, these are among the top reasons that lead to the erosion of a project’s profit margins. This is in addition to instances of inaccurate technical drawings or documentation or where there is a lack of labour and appropriate planning. This is why meticulous planning and a flexible, competent team capable of solving issues on-site are crucial for a project to be successful. Our long-term experience in electrical installation, shipbuilding and complex construction management projects has shown us that investing in prevention is more profitable than paying for the consequences”, Evaldas Kaziulis, a Director of sales at RNDV, says.

Mr Kaziulis continues: “Sometimes, to save money in the long run, you have to know where to invest. Once our new clients have had the opportunity to learn about the benefits of having a proper project management team, they very rarely want to try and cut these costs again. This is because it not only saves money but also gives you more stability, certainty and, therefore, peace of mind.”

A 20% to 30% Increase In Costs

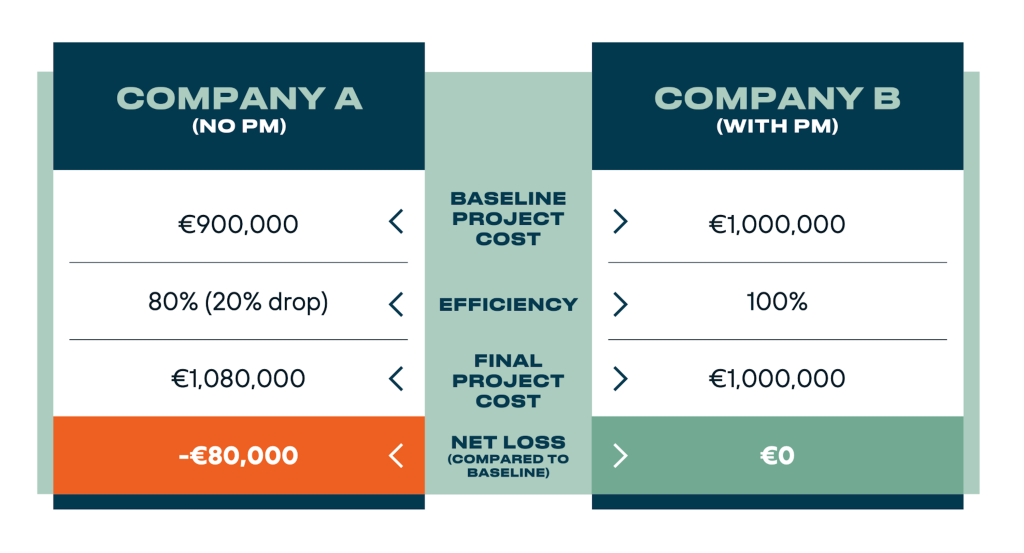

According to Giedrius Grėbliūnas, RNDV’s Chief Project Officer, downtime rates, common in the industry, are 20% to 30%. When downtimes are caused by issues such as delayed delivery of materials or errors in technical drawings, contractors typically claim additional payments. This leaves the client with two options: decline and potentially lose a contractor for future projects, or negotiate regarding the size of the claim and increase the project’s costs.

“In other words, when efficiency drops by 20%, the costs are likely to rise accordingly”, he points out.

To illustrate the point, Mr Grėbliūnas gives an example of two companies that are working on identical projects. “Let’s say the first company includes a project management team, maintaining 100% efficiency and keeping the project cost fixed at €1 million. In contrast, the second company chooses a slightly cheaper option, pricing their project at €900,000 but without a project management team. Due to a 20% drop in efficiency, their final project cost increases to €1,080,000, leading to an €80,000 loss.”

Efficiency Made Standard

Making 100% efficiency their standard, RNDV aims to eliminate waste in construction projects by implementing the “full kit” methodology. This significantly improves a project’s execution by ensuring that all necessary resources, materials and instructions are available before any work begins.

“This approach eliminates delays caused by missing components or incomplete guidance, fostering a seamless and uninterrupted workflow. By enabling workers to focus solely on task execution rather than sourcing materials or seeking clarifications, a full kit approach improves operational efficiency. Additionally, it reduces the likelihood of errors stemming from missing or inaccurate data, promoting consistency and reliability in task completion. This structured approach contributes to more accurate project timelines and greater predictability throughout a project’s lifecycle”, Mr Grėbliūnas says.

A Proper Team – The Key To Success

This is why, according to the experts, having a comprehensive team with a project manager, site manager, site foremen and team leaders is crucial – and something that is still often overlooked.

“A well-built contractor’s project management team is necessary to make sure that the full kit principle functions properly. In this way it can significantly contribute not only to sustaining but even increasing profits. Unfortunately, many players in the industry still overlook it, leading to significant losses of both money and time,” he remarks.

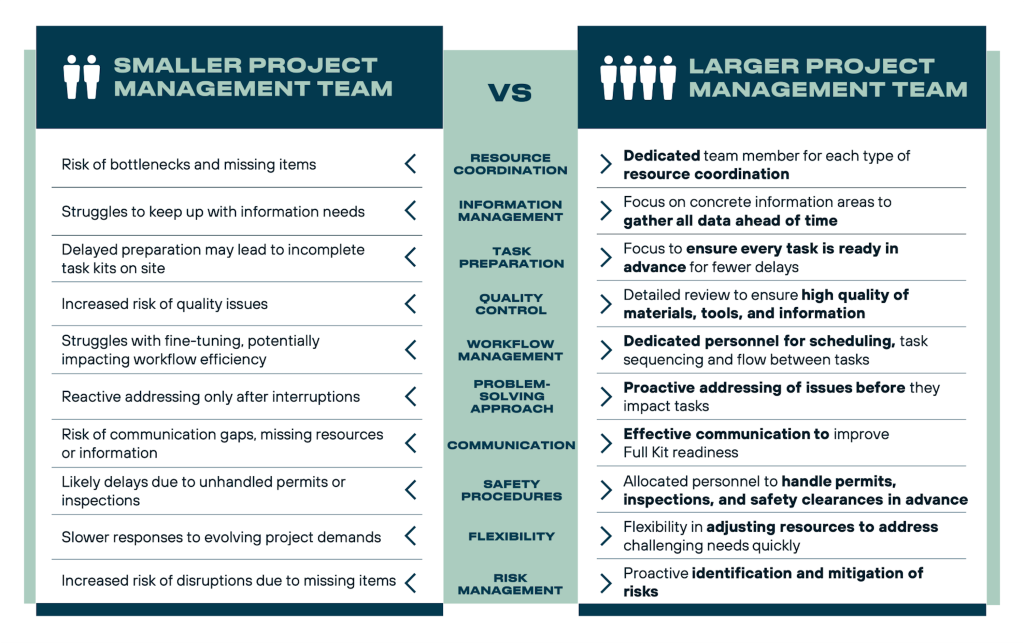

The size of the project management team required to effectively implement the full kit methodology largely depends on the project’s scale, complexity and the diversity of its resources.

“A well-structured team should be adequately staffed to ensure meticulous planning and resource coordination, in addition to timely communication. For larger or more complex projects, this may necessitate specialised roles, such as procurement managers, engineers, quality managers and more, who manage the comprehensive preparation process,” Mr Grėbliūnas notes.

However, more is not always better, and overstaffing can also lead to inefficiencies. It is, therefore, essential to strike a balance such that the project management team is large enough to handle the workload without having any redundancy within the team. “To put it simply, a proper project management team ensures that a project is carried out at 100% efficiency. This means transparency, cost-effectiveness and predictability,” he concludes.

About RNDV:

The RNDV group of companies has been operating since 2007 and has seen rapid growth, now boasting a team of more than 1,866 employees from 23 countries. Primarily focused on Western Europe, RNDV has increased its revenue by executing a wide range of electrical installation projects, including work on data centres, shipbuilding and repair, electromechanics, scaffolding and technical insulation, as well as renewable energy initiatives. The group’s revenue grew by 20% last year, reaching € 126.5 million.

Read more in the news: