Production of offshore metal structures services

Our project management and production team takes care of all the processes involved in the production of steel structures, from production planning and organisation to assembly, welding and quality control. We work on a wide range of projects, including offshore steel structures of varying complexity. Our specialists’ years of experience guarantee that we can produce steel structures tailored to your project.

Our steel fabrication work includes:

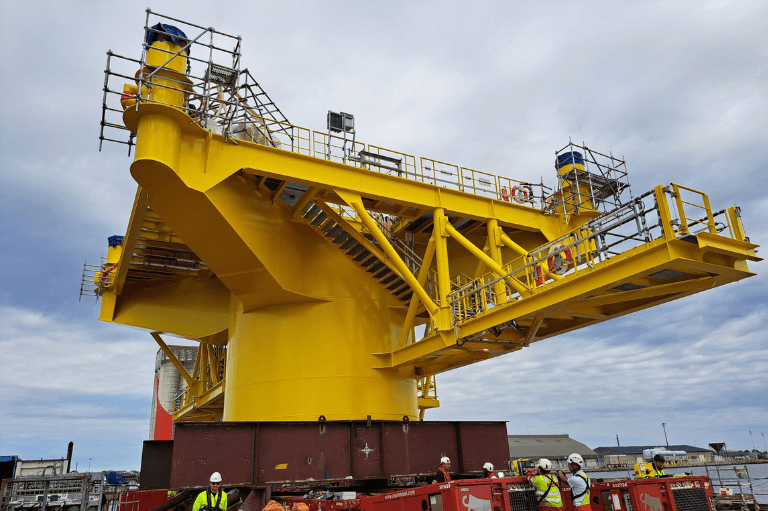

- Manufacture of substation platforms and supports

- Production of wind power plant supports

- Production of offshore steel equipment structures (steel outfitting)

- Production of oil and gas platforms

- Assembly and installation of pipelines.

RNDV – Trusted Partner

Our in-house highly qualified engineers oversee the entire production process from planning to implementation. We also have in-house quality inspectors who monitor the quality of the structures we produce and ensure that the work is carried out to the highest quality standards.

We deliver quality work to the required schedule. We use the most advanced LEAN methodology systems and modern construction management software in our project management. We use the latest welding technology and state-of-the-art equipment, which we maintain and calibrate on a regular basis to ensure high quality.

We adhere to the highest international standards to ensure the quality of our work (ISO 9001:2015; ISO 14001:2015; ISO 45001:2018, ISO 3834). We place great emphasis on occupational safety, which is taken care of by our separate Occupational Health and Safety (OSH) service.

Years of experience

We specialise in the shipping industry. Our teams are made up of certified professionals with 10+ years of experience in the industry.

Complex projects

We are ready to realise a project tailored to your individual needs. Our specialists produce steel structures of all types and complexities.

Experienced team

Our teams are made up of competent professionals who arrive on site with the necessary qualifications and are ready to implement the project efficiently.

Management Stages

Even before the start, the entire team clearly defines the goals of the project, the procedures, forms, and programs planned to be used in the project are reviewed, and additional training is carried out. The team starts with a very good understanding of the project, the desired results, and how those results will be achieved.

We must begin with efficient labor from the beginning. For this, we must anticipate and prepare for all conceivable scenarios in the first days.

Weekly plans and daily work packages with clearly defined daily tasks are in place for all projects. Deadlines are monitored using RNDV’s project management tool, where the planned schedule is uploaded, the team updates the quantity of work accomplished at the agreed-upon intervals, and it is easy to track whether we are progressing at the desired speed.

As a result, even before each day’s work begins, we must consider all potential barriers and solve them so that the workers do not incur any losses throughout the installation process. During preparation, drawings, materials, tools, information, instructions, and so forth are created.

As a result, having this information allows you to react quickly if efficiency is lower than intended and to solve the obstacles that caused it.

We carry on with project management processes, assess necessary changes, and schedule additional work.

All of this will be utilized in future initiatives and ensure the company’s continued improvement.

Projects

Completed projects

Projects

Completed projects

Contacts us