The fundamental principle of making money in the construction industry is straightforward: create value for your customer and get compensated in return. But RNDV Chief Project Officer (CPO) Giedrius Grėbliunas points out, “If only it would be so easy!”

“When it comes to building the right way, RNDV has the experience and knowledge to do so. In this post, I will share a few insights on where lies the source for a good construction process,“ asserts RNDV Chief Project Officer (CPO).

The Pillars of Construction Success

Let’s break down the construction process into two major phases: design and build. These can be visualized as two distinct “piles” of value. The first pile represents the value generated from an accurate and effective design. The second pile represents the value of executing that design flawlessly during construction. If both phases are executed correctly, the project is successful. Of course, additional steps could be included, but the premise remains consistent: success is a shared responsibility across all stages.

The Challenges of Traditional Construction Methods

Unfortunately, in many cases, traditional project delivery methods fail to capture the full value potential. For example, even if the design phase goes smoothly, inefficiencies can arise during the build phase. Miscommunication, lack of collaboration, and suboptimal processes often result in significant waste. This is where the “pile of value” from construction begins to erode.

Waste occurs when the build phase deviates from the plan—whether through delays, rework, or poor coordination between teams. These inefficiencies can lead to lost time, increased costs, and ultimately, a diminished final product.

The Productivity Problem in Construction

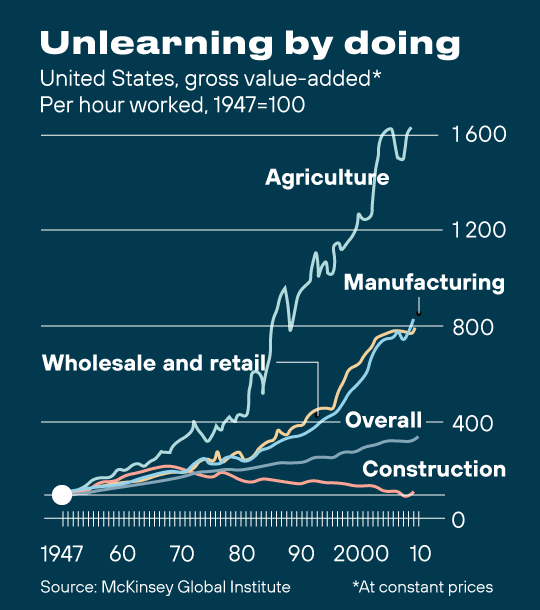

The issue of lost value in construction is not new. According to a study by the McKinsey Global Institute, productivity in construction has remained stagnant for decades. This chart (referenced in the study) shows gross value added per hour worked at constant prices since 1947. In essence, it reflects how productivity has evolved – or rather, stagnated – over time.

Giedrius Grėbliūnas notes that despite updated studies, the overall findings remain consistent. “Yes, in construction, we see various productivity levels across different project types. For example, multifamily buildings are more efficient than single-family homes, and industrial facilities outperform road construction. And you may wonder about the shipbuilding industry – I have an answer for you.”

The Complexity of Shipbuilding

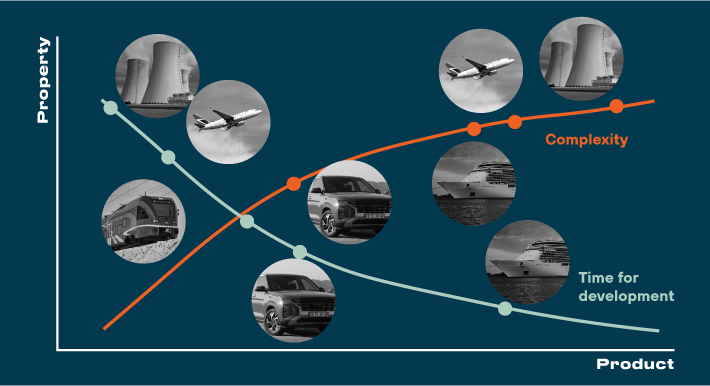

An interesting comparison is the shipbuilding industry. In a related study, products were measured based on two parameters: complexity and time for development. Ships, much like planes and nuclear power plants, are at the top of the scale in terms of both factors.

“Ships have a long development cycle. And the complexity does not fall behind planes and nuclear power plants. Combine the level of complexity with long development time and it is not hard to understand that you have a big challenge in front of you. In the time of the development, you have price erosion, change of personnel, pandemic, war, and other conditions that do not allow a project manager to sleep well each night,” highlights Giedrius Grėbliunas.

The construction industry’s productivity issues are well-documented, and it’s clear that change is necessary. The challenge now is to identify the root causes of inefficiency and develop solutions to address them. Giedrius Grėbliunas will explore these strategies in the next blog post – stay tuned!