Lina Momiroska, RNDV Business Compliance Project Manager

If the construction industry were football, working in an airport would be like playing in the UEFA Champions League: it demands top-tier expertise and opens the door to exceptional opportunities.

Airports are among the fastest-growing sectors. For RNDV, this growth represents more than business potential – it’s an opportunity to refine our internal processes and operate to the highest professional standards. We’ve successfully delivered projects in some of Europe’s major airports, including Copenhagen, Amsterdam, Stockholm and Madrid.

Certification and Compliance First

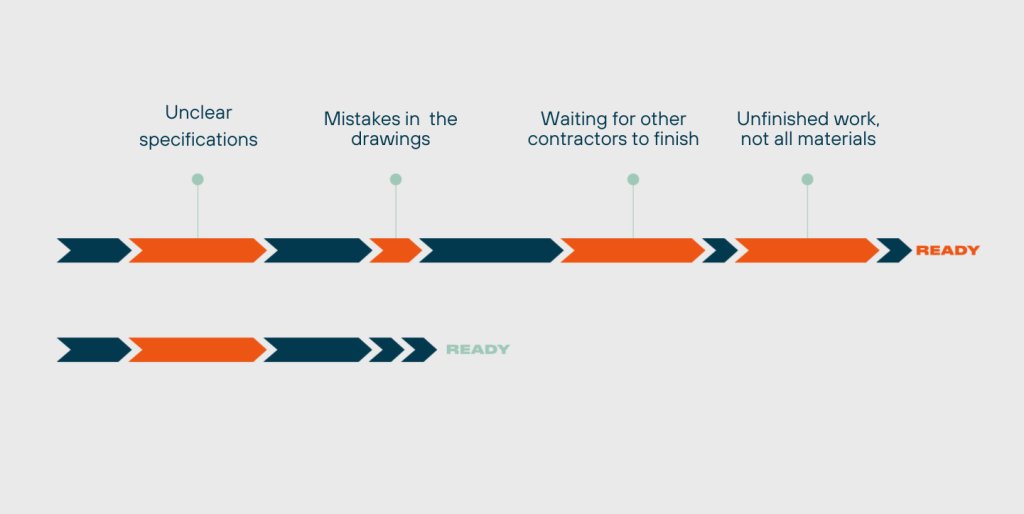

At airports, we carry out the electrical and mechanical installation of conveyor and sorting systems. While we have been successfully delivering such projects for over five years, airports stand out for one key reason: every phase – from documentation to execution – requires meticulous planning. Preparing and approving the required documentation alone can take up to eight weeks, and once work begins, it often has to be carried out on live, operational systems, where any delay can cause disruption.

That is why compliance plays a critical role in airport projects. At RNDV, our Business Compliance Managers are involved from the very beginning – identifying which certifications are required by the specific airport authority and ensuring that every employee has the necessary documentation. Depending on the country, this may include VCA, VCU, ISO certificates and HSE cards.

Additional registrations may also be required, and detailed background checks are often mandatory for all personnel. Once approval is granted, employees must pass an English-language test. Only after passing this test is a site badge issued, allowing entry to the airport premises.

It’s also important to note that only EU citizens can work in EU airports – this is a critical consideration when forming a project team.

The Highest Standards Require the Right Mix of Skills

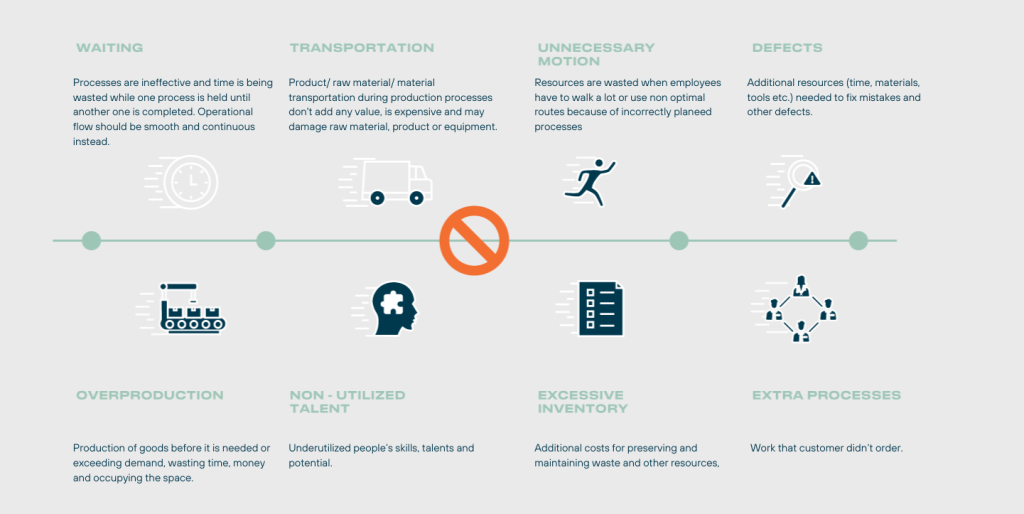

Working in airports requires a unique combination of expertise – rigorous regulatory compliance, precision-driven project management, and deep technical know-how in material handling systems.

That is why the projects we deliver in this sector are more than just success stories – they are a reflection of our commitment to the highest standards.

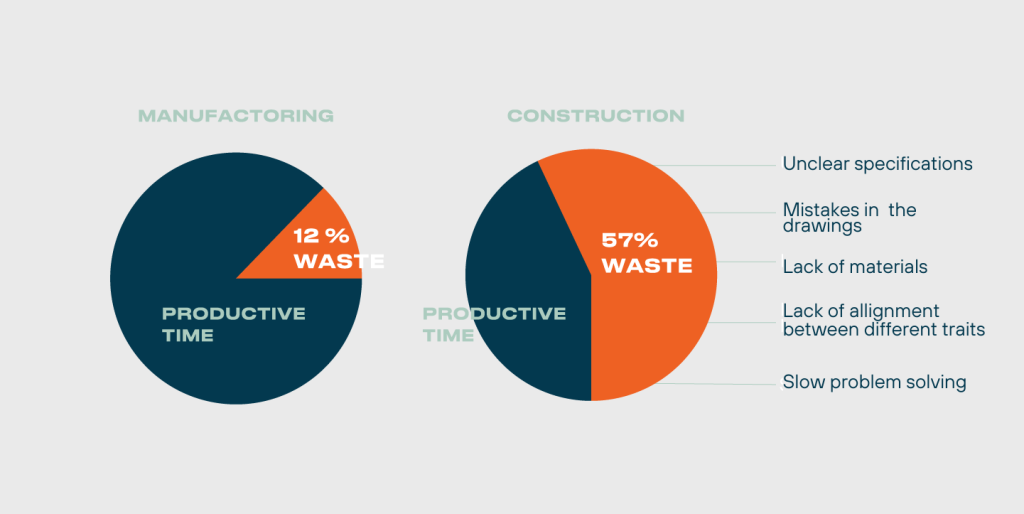

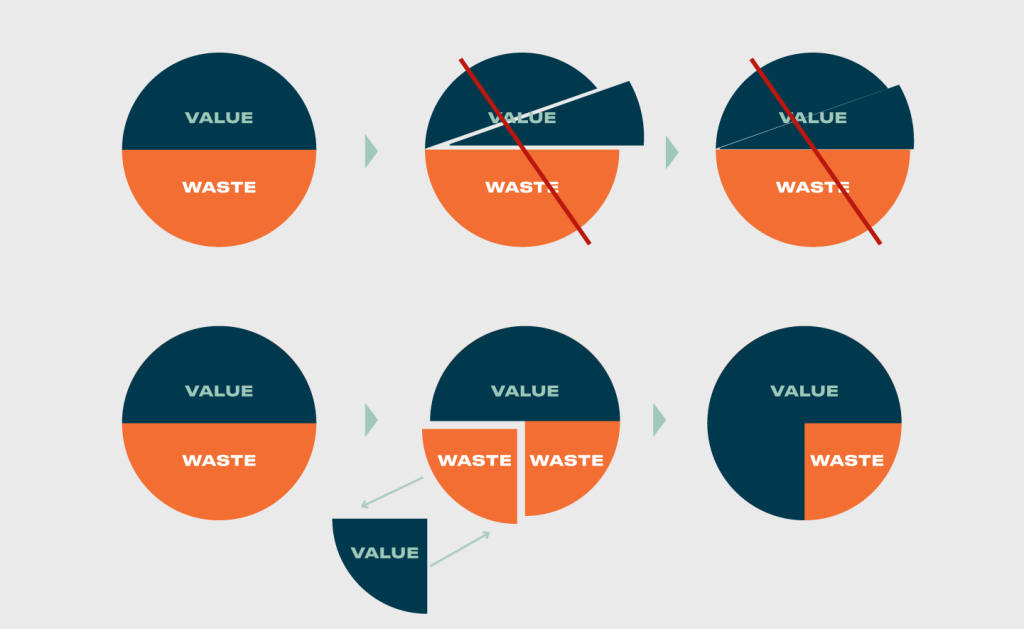

We set exceptionally high benchmarks for professionalism and quality at every stage of every project. Our experience in the aviation sector is not only a mark of trust, but also a valuable opportunity to learn, refine our processes, and apply these standards across other sectors.

We are always looking for partners who share our values – clarity, craftsmanship and reliability.

Looking for a partner who can deliver with precision in airport environments? Let’s connect.