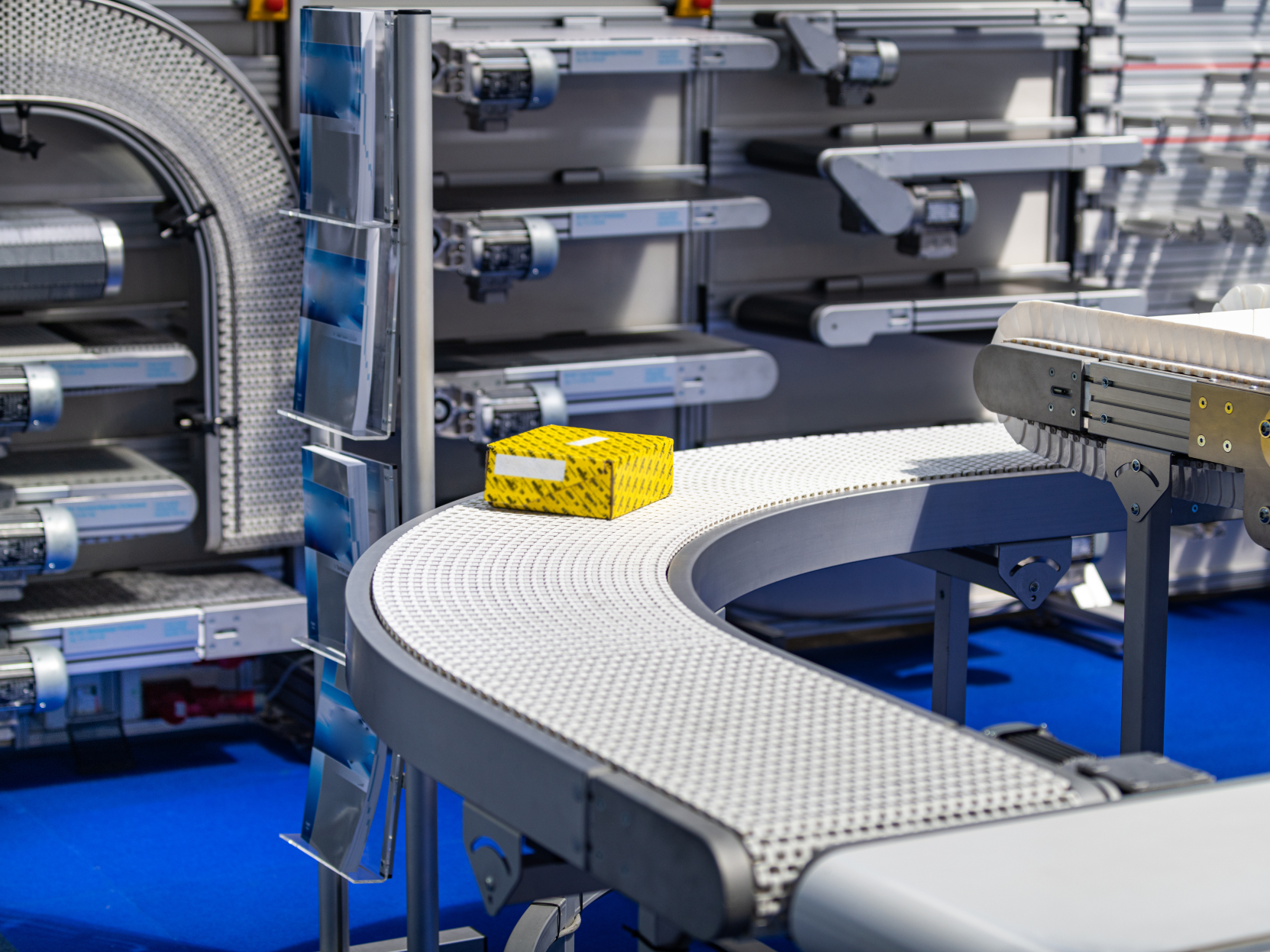

Installation of Conveyor Lines

Conveyor Line Installation Services

The RNDV team works with the world’s largest manufacturers of conveyor systems. When working in this highly dynamic market, we have to implement electrical, mechanical, and robotization projects of various scopes in different countries. The installation of conveyor lines requires a flexible and fast-reacting team, so we constantly train our specialists and prepare them for the successful implementation of projects.

Our clients value the experience gained by our employees, and we work with their teams to complete completely new projects as well as various modifications to existing systems. We always adapt to the client’s final needs and agree on appropriate time frames.

We work in a variety of logistics and distribution warehouses as well as industrial buildings. Amazon, DHL, DPD, medical warehouses, and smart electronic stores are among our facilities.

We install conveyor lines as follows:

- Unloading, Sorting, and Distribution of materials to the work areas

- Conveyor Mechanical Assembly

- Welding of Conveyor Belts

- Installation of Cable Routes

- Laying and Connecting Cables

- Installation and Connection of Switching Cabinets

- Commissioning and Testing of Pipelines

- Modification of Existing Lines to pre-agreed schemes

- Preparation of Technical Reporting Documentation according to the requirements of the client.

RNDV – Trusted Partner

We complete the work with high quality and within the time frame specified. To ensure high quality, we use cutting-edge technologies and cutting-edge equipment that we constantly maintain and calibrate. We are adaptable, respond quickly to changing circumstances, anticipate project issues in advance, and provide multiple solutions.

We adhere to the highest international standards to ensure the quality of our work in the company (ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 standards have been implemented). We pay special attention to work safety with our separate occupational safety and health (OSH) service.

Certified Specialists

Our employees have all of the certifications required to perform work to the highest quality and safety standards. At the RNDV Training Center, we test and improve the teams’ qualifications.

Work throughout Europe

Our team has completed projects in countries such as the Netherlands, Sweden, Belgium, Germany, and France.

Experienced Team

Our teams are made up of competent professionals who arrive at the facility with the necessary qualifications and are ready to start working on the project right away.

Management Stages of Solar Projects

Even before the start, the entire team clearly defines the goals of the project, the procedures, forms, and programs planned to be used in the project are reviewed, and additional training is carried out. The team starts with a very good understanding of the project, the desired results, and how those results will be achieved.

We must begin with efficient labor from the beginning. For this, we must anticipate and prepare for all conceivable scenarios in the first days.

Weekly plans and daily work packages with clearly defined daily tasks are in place for all projects. Deadlines are monitored using RNDV’s project management tool, where the planned schedule is uploaded, the team updates the quantity of work accomplished at the agreed-upon intervals, and it is easy to track whether we are progressing at the desired speed.

As a result, even before each day’s work begins, we must consider all potential barriers and solve them so that the workers do not incur any losses throughout the installation process. During preparation, drawings, materials, tools, information, instructions, and so forth are created.

As a result, having this information allows you to react quickly if efficiency is lower than intended and to solve the obstacles that caused it.

We carry on with project management processes, assess necessary changes, and schedule additional work.

All of this will be utilized in future initiatives and ensure the company’s continued improvement.

Completed projects

| COUNTRY | CATEGORY | TYPE | SCOPE OF WORK | |||||

|---|---|---|---|---|---|---|---|---|

| Norway | Land | Conveyor Line Installation | Installation and commissioning of the conveyor line, assembled the mechanical conveyor line and… |

|

||||

Contact us