RNDV has claimed victory at ScaffChamp, the prestigious international scaffolding championship. This year’s competition brought together 20 teams from 17 countries, including three strong contenders from Lithuania. In fact, skilled Lithuanian scaffolders were represented across several international teams. Yet it was RNDV who rose above the rest – proving themselves the most deserving of the title.

According to Gintautas Vitkevičius, Director of RNDV Industries, ScaffChamp is the highest form of professional recognition in the industry – a testament not only to the team’s speed and efficiency, but also to their strict adherence to top-tier safety standards. This year, RNDV took home two of the four main awards, including the one for health and safety – a core value in scaffolding operations.

The team’s main competitors included strong crews from Poland, Hungary, and Slovakia.

Preparation for the championship took six months, with RNDV bringing together scaffolders from ongoing projects in the Netherlands and Germany.

“This victory means a great deal to us,” said G. Vitkevičius. “The team returned energised and motivated – just like in professional sports, the entire company stood behind them with support. Since the win, we’ve seen a growing interest in the scaffolding profession, with more people reaching out to join our team. Clients are taking notice, too – we can now back up our words with proof: RNDV are world champions in scaffolding.”

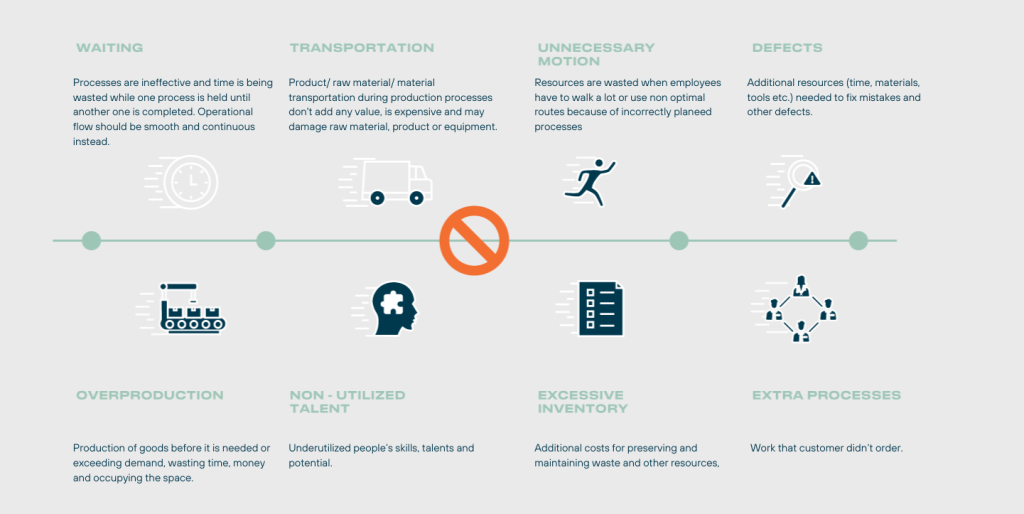

The RNDV team proved that scaffolding is far more than manual labour. It’s a demanding trade requiring precision, technical knowledge, and the ability to work independently. Scaffolders must think ahead, interpret blueprints, and make swift, effective decisions as a team.

Across Western Europe – in large-scale, long-term industrial projects – the demand for scaffolding services is high. RNDV teams are active in the Benelux countries, Germany, France, and Scandinavia.

For many motivated individuals, scaffolding presents a real opportunity. With just a few weeks of training alongside experienced professionals, they can join international projects, gradually building skills and expertise on the job. For young people in particular, scaffolding offers solid career prospects – with the potential to earn enough within a few years to fund a first home deposit, upgrade to a better car, or support family needs.